Steel Metric Round Head Bolts

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

Steel Metric Round Head Bolts: The Strong and Reliable Fastening Solution

When strength, precision, and international compatibility are critical, Steel Metric Round Head Bolts stand out as the top choice. These bolts, made from high-quality steel and designed to metric standards, offer exceptional durability, aesthetic appeal, and universal fitting for a wide range of applications.

What Are Steel Metric Round Head Bolts?

Steel Metric Round Head Bolts are fasteners featuring a smooth, rounded head and a steel shaft threaded according to metric measurements (millimeters). These bolts are widely used across industries that demand consistent quality, high strength, and adherence to global standards.

The rounded head of Steel Metric Round Head Bolts provides a clean finish and reduces the risk of snagging, while the steel construction ensures excellent tensile strength, making them suitable for both heavy-duty and decorative purposes.

Key Features of Steel Metric Round Head Bolts

Choosing Steel Metric Round Head Bolts brings numerous key features:

High Strength Material: Made from carbon steel, alloy steel, or stainless steel for superior mechanical properties.

Precise Metric Threading: Complies with ISO, DIN, or JIS metric standards for international use.

Smooth Round Head Design: Enhances appearance while minimizing hazards from exposed fasteners.

Corrosion-Resistant Coatings: Options include zinc plating, hot-dip galvanizing, or black oxide treatments.

Wide Range of Sizes: Available from M3 to M24 and beyond, with customizable lengths.

Enhanced Durability: Designed to withstand mechanical stress, vibration, and environmental factors.

Thanks to these features, Steel Metric Round Head Bolts guarantee superior fastening solutions for diverse applications.

Benefits of Steel Metric Round Head Bolts

The decision to use Steel Metric Round Head Bolts offers significant benefits:

Global Compatibility: Ideal for multinational projects and global supply chains.

Exceptional Load-Bearing Capacity: Perfect for structural, automotive, and industrial uses.

Aesthetic Appeal: The rounded head delivers a polished, finished look for visible installations.

Corrosion Protection: Suitable for both indoor and outdoor applications.

Long Service Life: Steel construction ensures long-term performance with minimal maintenance.

Easy Sourcing and Replacement: Standardized sizing allows for easy procurement and interchangeability.

For anyone needing reliable, robust fasteners, Steel Metric Round Head Bolts are a smart investment.

Common Applications of Steel Metric Round Head Bolts

Steel Metric Round Head Bolts are essential across numerous industries, including:

Automotive Industry: Securing vehicle frames, engines, and bodywork.

Construction and Infrastructure: Used in bridges, railways, and commercial buildings.

Furniture Manufacturing: Providing strong, neat connections in office and residential furniture.

Machinery and Heavy Equipment: Fastening machine components and heavy assemblies.

Marine Industry: Stainless steel variants resist corrosion in shipbuilding and docks.

Renewable Energy: Used in wind turbines, solar panel mounts, and hydroelectric structures.

Whenever strength, appearance, and global standardization are needed, Steel Metric Round Head Bolts deliver outstanding results.

How to Select the Right Steel Metric Round Head Bolts

Choosing the right Steel Metric Round Head Bolts involves careful consideration:

Material Selection: Carbon steel for general applications; stainless steel for corrosion resistance.

Bolt Size: Diameter (M6, M8, M10, etc.) and length should match design specifications.

Thread Type: Coarse or fine metric threads depending on the application needs.

Finish: Choose a finish based on exposure to moisture, chemicals, or extreme temperatures.

Mechanical Requirements: Ensure the bolt's tensile and shear strength meet load demands.

Compliance Standards: Confirm bolts meet required ISO, DIN, or JIS certifications.

Properly selected Steel Metric Round Head Bolts ensure maximum safety, longevity, and performance.

Installation Tips for Steel Metric Round Head Bolts

To maximize the performance of Steel Metric Round Head Bolts, follow these installation best practices:

Use Correct Torque Settings: Prevent over-tightening, which can weaken the bolt or the material.

Match Tools to Bolt Size: Use the right wrench or socket for a secure fit.

Apply Anti-Seize Lubricant: Recommended especially for stainless steel bolts to avoid galling.

Pre-Drill Pilot Holes: Helps with smooth bolt insertion and reduces material stress.

Periodic Inspection: Regularly check bolts for signs of loosening or corrosion, especially in dynamic applications.

Following these tips ensures that Steel Metric Round Head Bolts perform reliably under all conditions.

Why Choose Steel Metric Round Head Bolts?

Steel Metric Round Head Bolts are the fastening solution of choice when you demand strength, precision, and international compatibility. Their superior construction, corrosion-resistant finishes, and professional appearance make them indispensable for everything from construction to advanced machinery.

Whether you are assembling a complex industrial machine or enhancing structural integrity in buildings, Steel Metric Round Head Bolts provide the durability and reliability you need.

Conclusion

Steel Metric Round Head Bolts represent the ideal combination of strength, standardization, and visual appeal. Engineered from high-quality steel and crafted to metric specifications, Steel Metric Round Head Bolts ensure superior fastening performance in a vast array of industries and applications.

Upgrade your fastening solutions today with Steel Metric Round Head Bolts and experience the advantages of world-class quality and reliability.

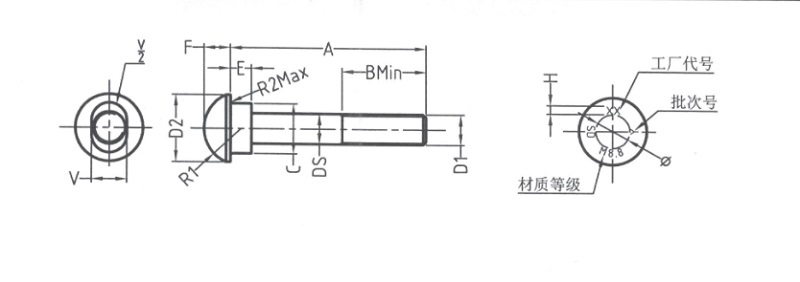

Product drawing