Round Head Short Square Neck Bolts

1.Product: ASME B18.5.2.1M Metric Round Head Short Square Neck Bolts

2. Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3. Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4. Support customer customization.

5. Professional sales and after-sales service, welcome to inquire at any time.

6. Delivery on time.

Round Head Short Square Neck Bolts: The Essential Fastener for Secure and Reliable Connections

In the world of industrial fastening, Round Head Short Square Neck Bolts stand out for their unique design and versatility. Whether used in wood construction, machinery assembly, or metal fabrication, Round Head Short Square Neck Bolts provide superior holding strength and alignment, making them an indispensable component for countless projects.

What are Round Head Short Square Neck Bolts?

Round Head Short Square Neck Bolts are a specialized type of carriage bolt characterized by a domed, round head and a short square neck directly beneath it. The square neck grips into the material—typically wood or metal—preventing the bolt from turning when a nut is tightened. This feature makes Round Head Short Square Neck Bolts ideal for applications requiring strong, tamper-resistant fastening.

Unlike standard carriage bolts with longer necks, Round Head Short Square Neck Bolts are designed for use in thinner materials or where a flush finish is necessary without compromising strength.

Key Features of Round Head Short Square Neck Bolts

Choosing Round Head Short Square Neck Bolts offers a range of benefits and critical features:

Round Domed Head: Provides a smooth, finished appearance and reduces the risk of snagging.

Short Square Neck: Locks into material to prevent bolt rotation during tightening.

High Strength Materials: Manufactured from steel, stainless steel, or galvanized steel for corrosion resistance and durability.

Tamper Resistance: The square neck ensures the bolt cannot be easily loosened from the head side, enhancing security.

Versatile Applications: Suitable for wood, metal, composites, and other materials.

Variety of Finishes: Available with plain, zinc-plated, hot-dip galvanized, or black oxide coatings.

Thanks to these robust features, Round Head Short Square Neck Bolts are widely trusted across multiple industries.

Benefits of Using Round Head Short Square Neck Bolts

The use of Round Head Short Square Neck Bolts provides a host of important advantages:

Secure Fastening: The square neck locks into place, preventing spinning and ensuring firm tightening.

Enhanced Durability: High-grade materials and coatings resist rust, corrosion, and wear.

Improved Aesthetics: The round head delivers a smooth, finished look ideal for visible installations.

Ease of Installation: Designed for quick assembly, especially when used with pre-drilled or punched holes.

Cost-Effective Solution: Provides long-lasting performance with minimal maintenance needs.

When strength, security, and appearance matter, Round Head Short Square Neck Bolts offer the ideal solution.

Common Applications of Round Head Short Square Neck Bolts

Round Head Short Square Neck Bolts are used in a variety of industries and projects, including:

Wooden Structures: Decks, bridges, fences, and wooden frames.

Metal Fabrication: Machinery frames, equipment enclosures, and steel constructions.

Automotive Industry: Securing body panels and structural components.

Furniture Manufacturing: Beds, chairs, tables, and cabinetry.

Public Infrastructure: Playground equipment, park benches, and signage.

The reliable grip and clean finish of Round Head Short Square Neck Bolts make them the go-to fastener for critical construction and manufacturing needs.

How to Select the Right Round Head Short Square Neck Bolts

To choose the best Round Head Short Square Neck Bolts for your project, consider the following factors:

Material Compatibility: Match the bolt material to the substrate to ensure optimal performance.

Size and Length: Select the appropriate diameter and length based on material thickness and load requirements.

Coating Type: Choose corrosion-resistant coatings for outdoor or harsh environments.

Thread Type: Determine if coarse or fine threads are better suited for your specific application.

Quantity Requirements: Purchase in bulk for larger projects to ensure consistency and save costs.

Using the correct Round Head Short Square Neck Bolts guarantees a secure, lasting connection for any application.

Installation Tips for Round Head Short Square Neck Bolts

Maximize the performance of your Round Head Short Square Neck Bolts with these helpful installation tips:

Pre-Drill Holes: For hardwood or metal, pre-drill holes sized to fit the bolt shaft to ensure proper seating of the square neck.

Use Proper Tools: Tighten the nut with a wrench or socket while holding the bolt head steady if necessary.

Do Not Over-Tighten: Avoid stripping threads or damaging the material by tightening only to the manufacturer's recommended torque.

Inspect Before Use: Always check bolts for defects or corrosion before installation.

Correct installation techniques will ensure the maximum strength and lifespan of your Round Head Short Square Neck Bolts.

Why Round Head Short Square Neck Bolts Are the Best Choice

The combination of high strength, anti-rotation design, and attractive appearance makes Round Head Short Square Neck Bolts the best choice for a wide range of fastening needs. Whether you are building a backyard deck, assembling heavy machinery, or constructing public infrastructure, Round Head Short Square Neck Bolts provide dependable performance every time.

Choosing quality Round Head Short Square Neck Bolts means choosing reliability, durability, and peace of mind for your most critical projects.

Conclusion

Round Head Short Square Neck Bolts are an essential fastener for secure, tamper-resistant, and long-lasting connections. With their superior design and wide-ranging applications, they are a must-have for professionals and DIYers alike.

Upgrade your fastening solutions with Round Head Short Square Neck Bolts and experience the perfect combination of strength, security, and simplicity today!

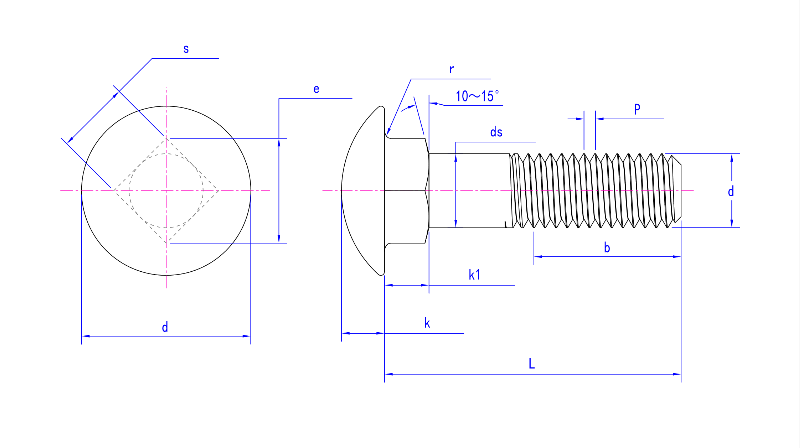

Product drawing