DIN 6923 Hexagon Flange Nuts

Product: DIN 6923 Hexagon Flange Nuts

Property Class:8,10,12,A2-70

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

DIN 6923 hexagonal flange face nut, also known as hexagonal welding nut, is a specially designed fastener. DIN 6923 hexagonal flange nut has a hexagonal shape and one or more flanges. The diameter of the flange is usually larger than that of the nut. There are also some raised teeth on the flange. These teeth are designed to increase the friction between the nut and the parts, thereby enhancing the stability of the connection. DIN 6923 hexagonal flange nuts are divided into different strength levels, which represent the tensile strength and yield strength of the nut and are suitable for different application scenarios.

Pictures

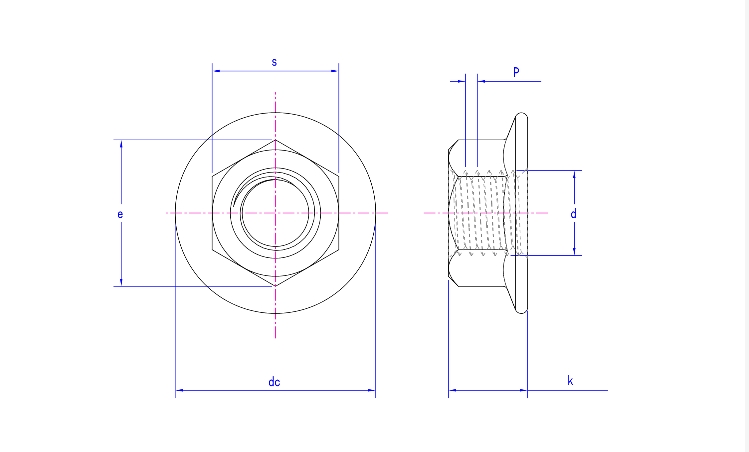

Product drawing

Product Specification

Size | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | |

P | 0.8 | 1.0 | 1.25 | 1.5 | 1.75 | 2.0 | 2.0 | 2.5 | |

dc max | 11.8 | 14.2 | 17.9 | 21.8 | 26.0 | 29.9 | 34.5 | 42.8 | |

e min | 8.79 | 11.05 | 14.38 | 16.64 | 20.03 | 23.36 | 26.75 | 32.95 | |

k | max | 5.0 | 6.0 | 8.0 | 10.0 | 12.0 | 14.0 | 16.0 | 20.0 |

min | 4.7 | 5.7 | 7.64 | 9.64 | 11.57 | 13.3 | 15.3 | 18.7 | |

s | max | 8.0 | 10.0 | 13.0 | 15.0 | 18.0 | 21.0 | 24.0 | 30.0 |

min | 7.78 | 9.78 | 12.73 | 14.73 | 17.73 | 20.67 | 23.67 | 29.16 | |

Support customer customization | |||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

Service

1. Product customization services:

According to the specific needs of customers, customized DIN 6923 hexagonal flange nuts of different sizes, materials, strength levels, etc. are provided.

Customization service can ensure that the nut fully meets the customer's equipment or project requirements, improving the reliability and stability of the connection.

2. Quality control and testing:

Strict quality control is carried out on the produced DIN 6923 hexagonal flange nuts to ensure stable and reliable product quality.

Provide necessary testing equipment and means to conduct quality testing on products to meet customer quality requirements.

3. Environmental protection and sustainability:

Manufacturers can pay attention to environmental protection and sustainability issues, ensure that the production process meets environmental requirements, and provide products that meet environmental standards.

In the product design and manufacturing process, we actively use environmentally friendly materials and processes to reduce the negative impact on the environment.

FAQ

1.What are the technical characteristics of DIN 6923 hexagonal flange nut?

Anti-loosening flange hexagonal nuts designed based on DIN 6923 standard, such as RIPP flange locking nuts with anti-skid teeth, can prevent the nut connection pair from loosening in a vibrating environment. This kind of nut adds anti-skid teeth on the bottom of the flange pad, and relies on the friction generated to achieve the locking effect.

2. Processing and heat treatment?

DIN 6923 hexagonal flange nuts are formed using self-tapping screws and undergo high temperature heat treatment. This treatment can ensure that the surface of the nut is passivated and flat, making it easier to tighten the handle, while avoiding damage to the inner wall of the steel pipe caused by mechanical polywelding and reducing installation time.