ASME B18.2.1-8 Hex Head Flange Bolts

Product: ASME B18.2.1-8 Hex Head Flange Bolts

Property Class: Gr307A, 307B, 325, A449, A490 2,5,8

Finish:Zinc Plating(Yellow Zinc, Zinc Blue,Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

Hex Head flange bolts are fasteners composed of a hexagonal head, a flange plate and a screw rod.

Pictures

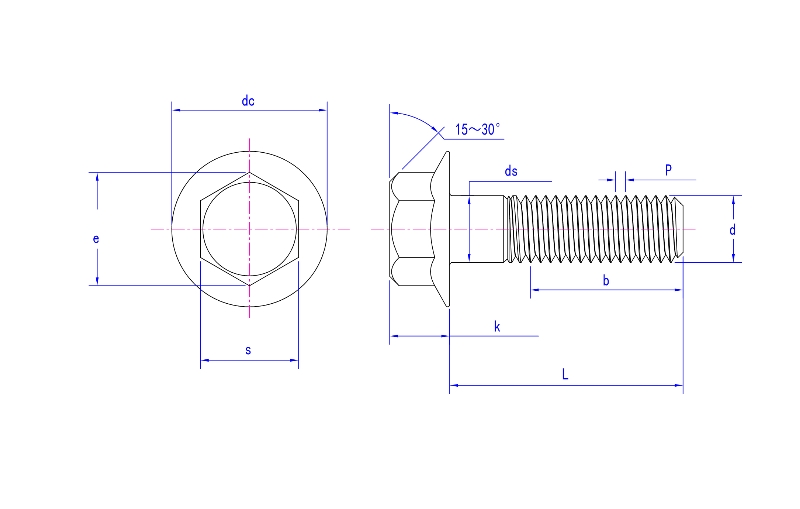

Product drawing

Product Specification

Size | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | |

P | 20|28|32 | 18|24|32 | 16|24|32 | 14|20|28 | 13|20|28 | 12|18|24 | 11|18|24 | 10|16|20 | |

ds | max | 0.25 | 0.3125 | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 |

min | 0.245 | 0.3065 | 0.369 | 0.4305 | 0.493 | 0.5545 | 0.617 | 0.741 | |

s | max | 0.375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.8125 | 0.9375 | 1.125 |

min | 0.367 | 0.489 | 0.551 | 0.612 | 0.736 | 0.798 | 0.922 | 1.125 | |

e | max | 0.433 | 0.577 | 0.65 | 0.722 | 0.866 | 0.938 | 1.083 | 1.299 |

min | 0.409 | 0.548 | 0.618 | 0.685 | 0.825 | 0.895 | 1.034 | 1.234 | |

dc max | 0.56 | 0.68 | 0.81 | 0.93 | 1.07 | 1.19 | 1.33 | 1.59 | |

k max | 0.28 | 0.32 | 0.39 | 0.46 | 0.51 | 0.57 | 0.62 | 0.73 | |

Support customer customization | |||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our enterprise has a specialised laboratory with digital hardness testers, microscopes, widely wide-spread trying out machines, axial pressure meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray checking out machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

Our service:

1. Customize ideal fasteners: Customize services based on the samples and drawings provided.

2. Perfect fastening solutions with 60 years of experience to solve your problems: wide selection of parts.

3. Professional manufacturer: All our fasteners are designed and manufactured according to buyers' specifications and performance.

4. Quality guaranteed: durability testing and key technology design to improve the service life of fasteners.

5. Cost-effectiveness: Wide selection of parts, supplied by professional factories, and competitive prices.

FAQ

1.About product quality

Question: How do you ensure the quality of your products?

Answer: We strictly follow international and industry standards for production. Each batch of products will undergo strict quality testing to ensure that the products meet the highest quality standards. At the same time, we use high-quality materials and advanced production processes to ensure the stability and durability of the products.

2.About customized services

Question: Can you provide customized services?

Answer: Yes, we provide personalized customized services. You can choose the appropriate material, size, surface treatment, etc. according to your specific needs. We will customize exclusive fastener products for you according to your requirements.