ISO 8677 Cup Head Square Neck Bolts with Large Head

Product: ISO 8677 Cup Head Square Neck Bolts with Large Head-Product Grade C

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

Carriage bolt is a type of fastener consisting of a head and a screw .

Pictures

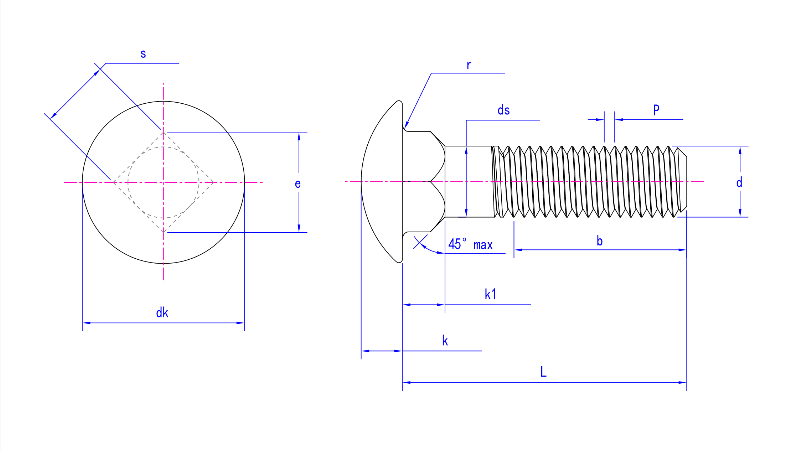

Product drawing

Product Specification

Size | M5 | M6 | M8 | M10 | M12 | M16 | M20 | |

P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | |

e min | 5.9 | 7.2 | 9.6 | 12.2 | 14.7 | 19.9 | 24.9 | |

dk | max | 13 | 16 | 20 | 24 | 30 | 38 | 46 |

min | 11.9 | 14.9 | 18.7 | 22.7 | 28.7 | 36.4 | 44.4 | |

ds | max | 5.48 | 6.48 | 8.58 | 10.58 | 12.7 | 16.7 | 20.84 |

min | 4.48 | 5.35 | 7.19 | 9.03 | 10.86 | 14.70 | 18.38 | |

k | max | 3.1 | 3.6 | 4.8 | 5.8 | 6.8 | 8.9 | 10.9 |

min | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | |

k1 | min | 2.9 | 3.4 | 4.4 | 5.4 | 7.2 | 11.1 | 14.1 |

max | 4.1 | 4.6 | 5.6 | 6.6 | 8.8 | 12.9 | 15.9 | |

s | max | 5.48 | 6.48 | 8.58 | 10.58 | 12.7 | 16.7 | 20.84 |

min | 4.52 | 5.52 | 7.42 | 9.42 | 11.3 | 15.3 | 19.16 | |

r max | 0.4 | 0.5 | 0.8 | 0.8 | 1.2 | 1.2 | 1.6 | |

Support customer customization | ||||||||

Some introduction about our company

Application

Our merchandise are broadly used in mechanical, electrical, automotive, constructing construction, railways, bridges, steamships, furnace safety and verbal exchange system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

Our service:

Professional manufacturer: All our fasteners are designed and manufactured according to buyers' specifications and performance.

Quality guaranteed: durability testing and key technology design to improve the service life of fasteners.

Cost-effectiveness: Wide selection of parts, supplied by professional factories, and competitive prices.

Customize ideal fasteners: Customize services based on the samples and drawings provided.

Perfect fastening solutions with 60 years of experience to solve your problems: wide selection of parts.

FAQ

1.About the cooperation process

Question: How do we start cooperation?

Answer: You can contact us through our official website, phone, email or direct visit. We will provide detailed product introduction and quotation according to your needs. After both parties reach an agreement, we can sign a formal cooperation agreement and start production. We will follow up the progress of the order throughout the process to ensure that the product is delivered on time.

2.About Industry Certification

Question: Are your products certified by the industry?

Answer: Yes, our products have passed a number of industry certifications and standard tests, such as ISO 9001 quality management system certification, CE certification, etc. These certifications prove that our products meet international and industry standards and have excellent quality and performance.