Flat Head Rivets

Product: Flat Head Rivets

Property Class:4.8

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Q235

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

Flat Head Rivets

Overview

Flat Head Rivets are versatile and widely used permanent fasteners designed to create strong, secure joints in a variety of materials. With a low-profile head that sits flush with the surface after installation, Flat Head Rivets are ideal for applications requiring a smooth finish and minimal protrusion. Whether in metalworking, construction, automotive, or aerospace industries, Flat Head Rivets offer a reliable, tamper-resistant solution for permanent joining.

Pictures

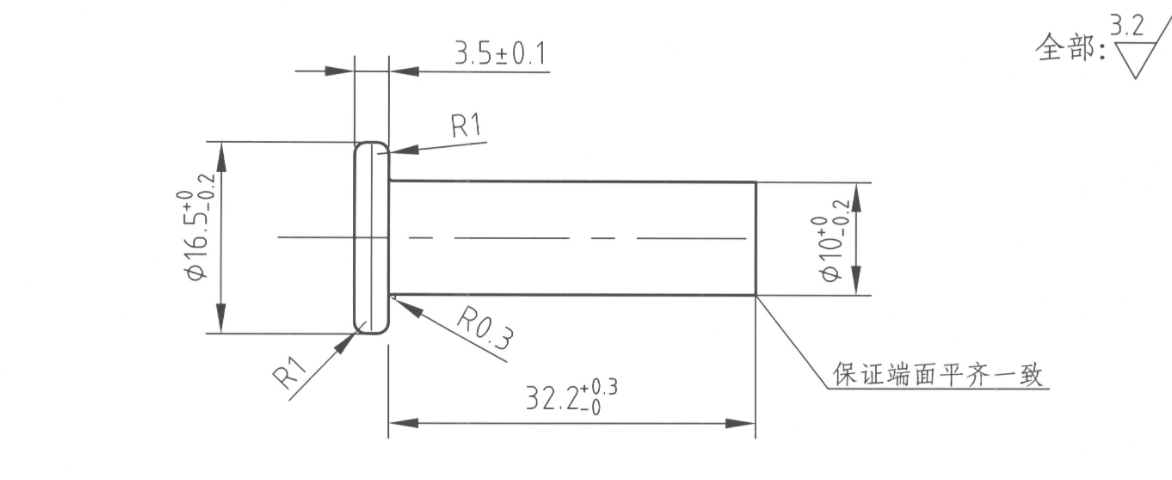

Product drawing(M10×32)

Key Features of Flat Head Rivets

Flush Surface Finish

The defining feature of Flat Head Rivets is their wide, flat head, which becomes nearly level with the material surface once installed. This makes Flat Head Rivets an excellent choice for aesthetic or aerodynamic applications.Strong and Durable Joint

Once installed, Flat Head Rivets provide a solid mechanical bond that resists shear and tensile forces, ensuring long-term durability even under vibration or load.Material Compatibility

Flat Head Rivets are available in various materials such as aluminum, steel, stainless steel, brass, and copper. This allows for compatibility with a wide range of base materials and environmental conditions.Wide Size Range

Offered in a variety of diameters and lengths, Flat Head Rivets can be selected based on the thickness and type of materials being joined.Manual and Automated Installation

Flat Head Rivets can be installed using hand tools for low-volume needs or automated riveting systems for high-speed production lines, ensuring flexibility in application.

Applications of Flat Head Rivets

Automotive Industry

Flat Head Rivets are used to join body panels, frame components, and interior assemblies, offering secure fastening with a clean surface appearance.Aircraft and Aerospace

In aircraft manufacturing, Flat Head Rivets are preferred in aerodynamic zones where flush surfaces are crucial to performance and safety.Electronics and Appliances

These rivets provide secure attachment of components inside devices, maintaining structural integrity without interfering with the form factor.Metal Fabrication

Sheet metal enclosures, casings, and frames benefit from the seamless finish and strong bond provided by Flat Head Rivets.Furniture and Cabinetry

Flat Head Rivets offer a durable, flush-fastening option for wooden and composite materials in furniture manufacturing.

Advantages of Flat Head Rivets

✅ Flush Finish for Better Aesthetics

Ideal for surfaces that must remain smooth or be coated after assembly.✅ High Strength and Durability

Designed to withstand shear and tensile stress without loosening or failure.✅ Permanent, Tamper-Resistant Joints

Once installed, Flat Head Rivets cannot be easily removed, making them perfect for safety-critical or high-security applications.✅ Corrosion-Resistant Options Available

Stainless steel or coated versions of Flat Head Rivets ensure long-term resistance to rust and corrosion.✅ Cost-Effective Fastening Solution

Flat Head Rivets provide high strength-to-cost performance, especially in mass production.

Why Choose Flat Head Rivets?

If your project demands a low-profile, permanent fastener that delivers both strength and a professional finish, Flat Head Rivets are the ideal solution. With reliable performance across a broad range of industries and environments, Flat Head Rivets meet both functional and aesthetic requirements without compromise.

Flat Head Rivets offer consistent, secure, and clean fastening for industrial and commercial applications. Their high-performance design, ease of use, and broad adaptability make Flat Head Rivets a trusted choice for engineers, manufacturers, and builders around the world.