Round Head Square Neck Bolts ASME B18.5-2

Product: Round Head Square Neck Bolts ASME B18.5-2

Property Class: Gr307A, 307B, 325, A449, A490 2,5,8

Finish:Zinc Plating(Yellow Zinc, Zinc Blue,Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

Round head square neck bolts in ASME B18.5-2 are generally considered a type of carriage bolt. Carriage bolts, also known as round head square neck screws, are bolts with a round head and a square neck. Round head square neck bolts have a round head and a square neck. This design can provide a larger contact area and increase the friction between the bolt and the connecting piece, thereby providing a better tightening effect. Additionally, the square neck prevents the bolt from slipping or turning when rotated, further ensuring the stability of the connection. Round Head Square Neck Carriage Bolts ASME B18.5-2(including round head square neck bolts) are widely used in a variety of industries, especially in joints where strength and reliability are required, such as vehicle manufacturing, mechanical engineering and the construction industry. In these applications, carriage bolts can effectively join two parts with through holes and, by mating with nuts, achieve tightness and retention.

Pictures

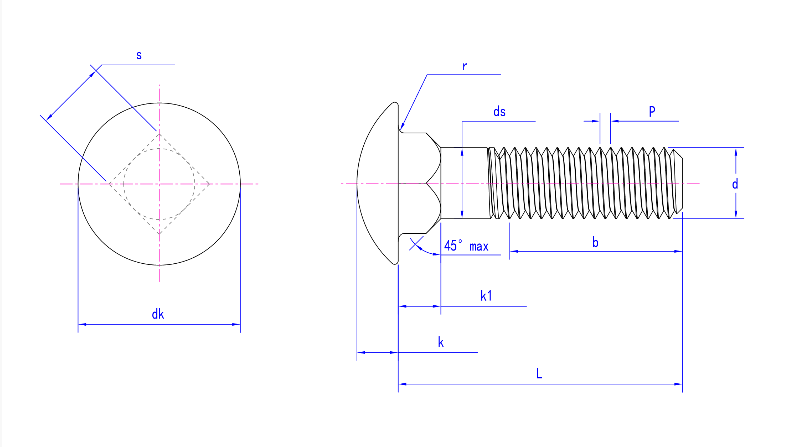

Product drawing

Product Specification

Size | No.10 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 7/8 | 1 | ||

ds | max | 0.199 | 0.26 | 0.324 | 0.388 | 0.452 | 0.515 | 0.642 | 0.768 | 0.895 | 1.022 | |

min | 0.159 | 0.213 | 0.272 | 0.329 | 0.385 | 0.444 | 0.559 | 0.678 | 0.795 | 0.910 | ||

dk | max | 0.469 | 0.594 | 0.719 | 0.844 | 0.969 | 1.094 | 1.344 | 1.594 | 1.844 | 2.094 | |

min | 0.436 | 0.563 | 0.688 | 0.782 | 0.907 | 1.032 | 1.219 | 1.469 | 1.719 | 1.969 | ||

k | max | 0.114 | 0.145 | 0.176 | 0.208 | 0.239 | 0.27 | 0.344 | 0.406 | 0.459 | 0.531 | |

min | 0.094 | 0.125 | 0.156 | 0.188 | 0.219 | 0.25 | 0.313 | 0.375 | 0.438 | 0.500 | ||

s | max | 0.199 | 0.260 | 0.324 | 0.388 | 0.452 | 0.515 | 0.642 | 0.768 | 0.895 | 1.022 | |

min | 0.185 | 0.245 | 0.307 | 0.368 | 0.431 | 0.492 | 0.616 | 0.741 | 0.865 | 0.990 | ||

k1 | max | 0.125 | 0.156 | 0.187 | 0.219 | 0.250 | 0.281 | 0.344 | 0.406 | 0.469 | 0.531 | |

min | 0.094 | 0.125 | 0.156 | 0.188 | 0.219 | 0.25 | 0.313 | 0.375 | 0.438 | 0.500 | ||

r max | 0.031 | 0.062 | ||||||||||

Support customer customization | ||||||||||||

Some introduction about our company

Application

Jinan Star Company specializes in the production of fastener products. Our bolts, nuts and other products are widely used in machinery, railways, automobiles, construction, electrical, bridges, communications, firefighting and other industries.

Workshop

The workshop of Jinan Star Fastener Co., Ltd. is the core area of the company's production and manufacturing, with advanced production equipment. The reasonable layout of the workshop and the scientific production process ensure the efficient production and high-quality output of fastener products.

Certification

Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification through the scientific management of leaders of various departments and the pursuit of high quality for bolts and other fasteners. In addition, the laboratory owned by Star Company has obtained the certification in 2017. It passed the national CNAS certification in 2018, and the company passed the European CE certification in 2018.

Testing Equipment

Jinan Star Fastener Company attaches great importance to product quality and is equipped with complete quality inspection equipment, such as tensile testing machines, torque testers,metallographic microscopes, optical projectors, salt spray test chambers, coating thickness gauges, etc., which are used to test the tensile strength and elongation of fastener products and evaluate the mechanical properties of products. These equipment ensure that every link from raw materials to finished products can be strictly controlled in quality.

Production equipment

In order to meet the needs of different customers, the company has introduced a series of advanced production equipment, such as multi-station cold heading machines, thread rolling equipment, heat treatment equipment, shot blasting machines, sand blasting machines, electroplating lines and other surface treatment equipment, and fully automatic packaging equipment. These equipment not only improve production efficiency, but also ensure the consistency and stability of product quality.

Packing

1. According to the specific needs of customers, customize the size, material, grade and other parameters of ASME B18.5-2 round head square neck bolts.

2. Provide consultation on the technical parameters, installation methods, usage precautions, etc. of ASME B18.5-2 round head square neck bolts. We have a professional technical team to answer the problems encountered by customers during use.

3. Conduct strict quality inspection on the produced ASME B18.5-2 round head square neck bolts to ensure that the products comply with the ASME B18.5-2 standard and customer requirements.

4. We cooperate with a number of logistics companies to ensure that products can be delivered to your designated location quickly and safely.

FAQ

1. Does the product comply with ASME B18.5-2 standards?

Answer: Our products are produced in strict accordance with ASME B18.5-2 standards, you can use them with confidence.

2. How long is the delivery cycle of the product?

A: The delivery lead time depends on the order quantity and production plan. We will arrange production and shipment as soon as possible according to your needs.

3. What is the price of the product?

Answer: Product price depends on factors such as material, size, performance level, etc. We will provide reasonable quotations based on your needs.