Bolt Square Neck

1.ISO 8677 Cup Head Square Neck Bolts with Large Head-Product Grade C

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Bolt Square Neck: The Perfect Fastener for Secure Connections

The Bolt Square Neck is a critical component for projects that require strength, stability, and resistance to rotation. Designed for use in wood, metal, and construction applications, the Bolt Square Neck offers a superior fastening solution by ensuring a tight and stable grip. Whether you are building outdoor structures or assembling machinery, choosing the right Bolt Square Neck can significantly impact the durability and safety of your project.

What Is a Bolt Square Neck?

A Bolt Square Neck is a type of fastener that features a rounded head with a square-shaped section just beneath it. This design allows the Bolt Square Neck to fit snugly into a square hole or embed itself into softer materials like wood. Once the bolt is tightened, the square neck prevents rotation, making it easier to fasten securely without needing a second tool to hold the bolt head.

Features of a Bolt Square Neck

Square Neck Design: The distinctive square neck locks into place to prevent spinning during installation.

Smooth Domed Head: Provides a neat, low-profile finish while avoiding material damage.

Durable Materials: The Bolt Square Neck is often made from steel, stainless steel, or galvanized metal to resist rust and wear.

Versatile Sizes: Available in a wide range of lengths, diameters, and threading options to suit various applications.

The Bolt Square Neck is specifically engineered to combine ease of installation with long-term holding power, making it indispensable for many industries.

Applications of a Bolt Square Neck

The Bolt Square Neck is highly versatile and used across numerous sectors:

Woodworking: Perfect for joining wooden beams, decking, and furniture.

Construction: Commonly used in structural assemblies, fencing, and framing.

Automotive: Helps in assembling body parts and other critical connections.

Industrial Machinery: Ensures stable fastening of equipment and mechanical parts.

Marine: Galvanized Bolt Square Neck options are ideal for high-moisture environments.

Its ability to prevent turning under torque makes the Bolt Square Neck particularly useful in dynamic or load-bearing applications.

Advantages of Choosing a Bolt Square Neck

Enhanced Stability: Reduces the risk of loosening under pressure or vibration.

Efficient Installation: Requires less manual effort to secure firmly.

Corrosion Resistance: Galvanized and stainless steel versions withstand tough environments.

Aesthetic Finish: Smooth head maintains a clean and professional appearance.

Cost-Effective: The Bolt Square Neck offers a long lifespan, minimizing maintenance and replacement costs.

Using a Bolt Square Neck ensures your project remains reliable over time, even in demanding conditions.

How to Select the Right Bolt Square Neck

Choosing the correct Bolt Square Neck involves several considerations:

Material Compatibility: Match the bolt material to your project's needs (e.g., stainless steel for marine use).

Size and Thread Type: Ensure the bolt dimensions fit your application’s load requirements.

Environmental Factors: Use coated or galvanized bolts for outdoor and moisture-prone areas.

Installation Method: Confirm that the hole size matches the square neck dimensions for a secure fit.

Proper selection of the Bolt Square Neck can significantly enhance both the performance and lifespan of your assembly.

Conclusion

The Bolt Square Neck is a practical, reliable, and high-performance fastener for a wide range of industrial, construction, and DIY projects. Its unique design provides enhanced resistance to rotation, superior load-bearing capabilities, and an aesthetically pleasing finish. Whether you are building a deck, erecting a fence, or assembling complex machinery, investing in a quality Bolt Square Neck ensures strength, security, and long-lasting results.

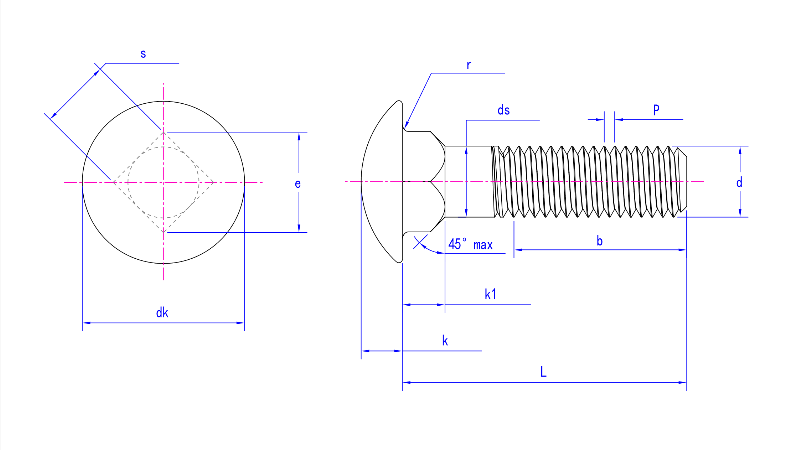

Product drawing